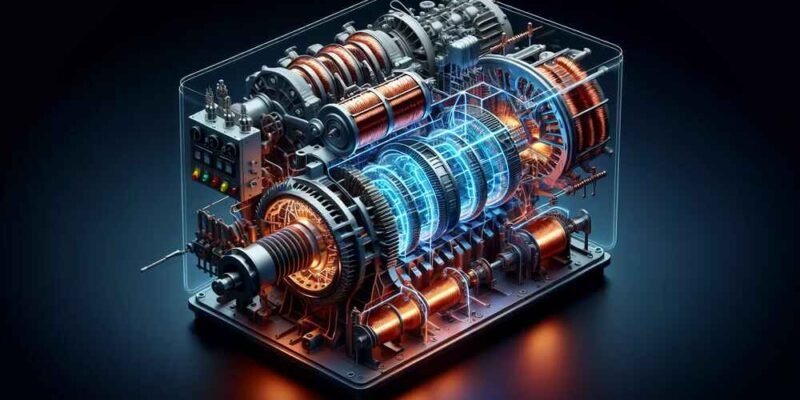

As seen earlier in this article, three-phase generators are a key component in power generation worldwide. Most generators in use today are single-phase generators, in which power is supplied through one cycle of AC voltage, while three-phase generators supply power through three different cycles of AC voltage. This three-phase power system has been recommended because of its effectiveness, reliability, and compatibility with heavy demands.

What is the Three-Phase Generator?

A three-phase generator is, therefore, an electrical generator that generates a three-phase alternating current. It comprises three distinct groups of coils wound on a single magnetic circuit. These windings are displaced by 120 degrees, giving rise to three separate types of electrical power. The three-phase system provides a higher degree of accuracy in electricity delivery compared to single-phase systems, and it is advantageous when it comes to supplying large machinery and many commercial establishments.

Benefits of Three-Phase Generators

Efficiency

As mentioned, three-phase generators are more effective than single-phase ones. This means that there are fewer energy losses due to continuous and smooth power output, which in turn implies that the power is used more optimally. This results in improved performance and reduced operation costs.

Power Capacity

Three-phase generators can handle larger electrical loads than single-phase generators. This is very important, especially in industries where most machines use a lot of power. Power distribution in three phases minimizes the chances of overloading and sustains optimal control in the circulation process.

Reduced Vibration

Three-phase power is balanced in nature, reducing mechanical stresses and vibrations on the equipment. This increases the lifespan of the generator and the machinery connected to it, hence incurring lower maintenance costs.

Improved Power Quality

The three-phase system ensures consistent and constant voltage, reducing fluctuations and voltage drops. This improves the quality of electricity, which is critical for appliances such as computers, electrical machines, and other sensitive equipment.

Smaller Generator Size

A three-phase generator of the same output rating can be more compact and weigh less compared to single-phase generators. This is because the space developed has common access points, which makes more efficient use of space and resources, enhancing ease of installation in industrial environments.

Applications of Three-Phase Generators

Industrial Operations

In manufacturing plants, factories, and industrial facilities, three-phase generators supply power to heavy equipment, production zones, and large motors. These generators are preferred in such situations due to their ability to handle high power loads, especially at start-up.

Commercial Buildings

Commercial facilities such as offices, malls, and hotels usually use three-phase generators to meet power requirements for air conditioning, lifts, and lights. Three-phase power reliability and effectiveness ensure that operations in commercial buildings continue to run as planned.

Data Centers

Maintaining data centers requires a constant power supply for servers and other IT infrastructure. Three-phase generators ensure uninterrupted power, enabling data centers to process large amounts of data without power failure.

Construction Sites

Three-phase generators power machinery such as cranes, drills, and pumps at construction sites. Construction machinery requires high power capacities, which three-phase generators can efficiently provide.

Factors to Consider when Selecting a Three-Phase Generator

Power Requirements

Your application’s power requirements should be evaluated before selecting a generator. Determine the power demand for each wiring and ensure the generator can handle the load. Other considerations include future power demands and whether the generator will still meet requirements.

Generator Size and Capacity

Based on your needs, select a generator of the right size and output. A small generator may be inadequate to supply the required power, while a large generator may be costly to acquire.

Fuel Type

Three-phase generators can use different fuel types, such as diesel, natural gas, or propane. Choose a fuel type that offers the most convenience for your operations and aligns with your financial capacity.

Maintenance and Service

Maintaining the generator is essential to ensure it operates correctly. Before selecting a generator, ensure that service options are readily available and that spare parts are easy to obtain.

Environmental Considerations

Consider environmental factors such as pollution emissions and noise levels. Some generator models have environmentally friendly features, such as reduced noise production.

In summary, three-phase generators offer numerous benefits for efficiency, power capacity, and reliability. They are indispensable for industrial or commercial use and in applications where high power demands are unavoidable. Understanding the functionality and uses of three-phase generators enables you to make informed decisions when selecting and using these powerful machines. For industrial, commercial, and construction applications, three-phase generators provide the heavy-duty power needed for reliable and efficient operations.

Do Read: Why IT Consulting is Key to a Comprehensive Cybersecurity Plan