Selecting the proper electronics manufacturer for Printed Circuit Board (PCB) assembly is a critical decision that can impact your product’s quality, efficiency, and overall success. Whether developing a new electronic device or improving an existing one, partnering with a reliable electronic manufacturing company is essential. This article provides a comprehensive guide on choosing the best manufacturer for your PCB assembly needs, focusing on Australian-based printed circuit board assembly services.

Understanding PCB Assembly

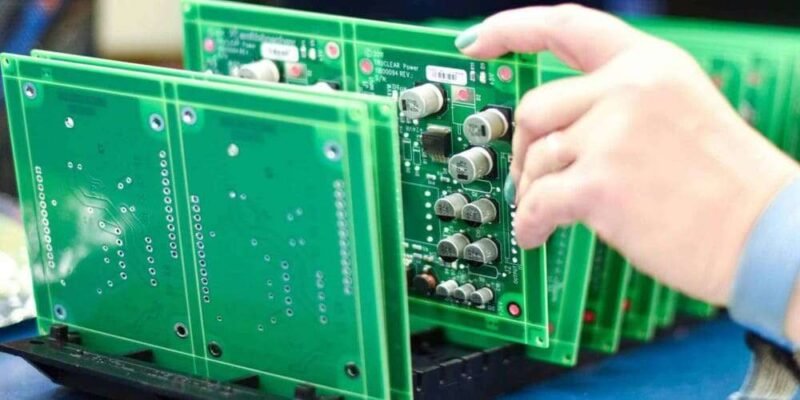

PCB assembly is soldering and assembling electronic components onto a printed circuit board. This process includes several steps: component placement, soldering, and inspection. The complexity of PCB assembly can vary depending on the design and functionality of the electronic device, making it crucial to choose a manufacturer with the right capabilities and expertise.

Why Choosing the Right Manufacturer Matters

Selecting the proper manufacturer ensures your electronic products’ quality, reliability, and performance. A reputable electronic manufacturing company can provide the technical expertise, quality control, and customer support needed to bring your product to market successfully. Conversely, choosing the wrong partner can lead to production delays, higher costs, and subpar products that can damage your brand’s reputation.

Key Factors to Consider When Selecting an Electronics Manufacturer

Experience and Expertise

Experience and expertise are critical factors when choosing a manufacturer. Look for companies with a proven track record in PCB assembly and experience in your specific industry. An experienced manufacturer will know your project’s challenges and requirements, ensuring a smoother production process and higher-quality outcomes.

Quality Assurance and Certifications

Quality assurance is essential in PCB assembly. Ensure the manufacturer has robust quality control processes and holds relevant certifications, such as ISO 9001. These certifications indicate that the manufacturer meets international quality management and production process standards.

Technological Capabilities

The manufacturer’s technological capabilities are crucial for ensuring they can meet your specific requirements. Evaluate their equipment, software, and production techniques to ensure they are up-to-date and capable of handling complex PCB designs. Advanced technologies can improve precision, efficiency, and overall product quality.

Customization and Flexibility

Your project may require custom solutions or adjustments during the production process. Choose a manufacturer that offers customization and flexibility to accommodate your specific needs. A flexible partner can adapt to changes in design, production volumes, and timelines, ensuring your project stays on track.

Cost and Value

While cost is essential, it should not be the sole deciding factor. Evaluate the manufacturer’s overall value, including quality, reliability, and customer support. A slightly higher upfront cost may be justified if it results in better quality and fewer issues.

Lead Time and Delivery

Timely delivery is crucial for meeting your project deadlines and getting your product to market. Assess the manufacturer’s lead time and delivery capabilities to ensure they can meet your schedule. Reliable manufacturers will have efficient production processes and logistics to minimize delays.

The Benefits of Australian-Based PCB Assembly Services

Opting for Australian-based printed circuit board assembly services offers several advantages:

- Proximity and Communication: Working with local manufacturers facilitates better communication and collaboration, reducing the risk of misunderstandings and delays.

- Quality Standards: Australian manufacturers are often subject to stringent quality and regulatory standards, ensuring high-quality products.

- Support for Local Economy: Choosing local manufacturers supports the Australian economy and can lead to more sustainable business practices.

How to Evaluate Potential Manufacturers

Conducting Background Research

Start by researching potential manufacturers online. Look for reviews, testimonials, and case studies that provide insights into their reputation and performance. Industry forums and professional networks can also be valuable resources for recommendations.

Requesting Quotes and Samples

Contact multiple manufacturers to request quotes and samples of their work. Comparing quotes will help you understand the cost landscape while evaluating samples, giving you a sense of their quality and capabilities. Pay attention to the details and craftsmanship of the samples provided.

Visiting Manufacturing Facilities

Visit the manufacturing facilities of the shortlisted manufacturers. A site visit lets you see their operations firsthand, assess their equipment and processes, and meet the team. It also provides an opportunity to discuss your project and address any concerns.

Conclusion

Choosing the right electronic manufacturing company for PCB assembly is a critical decision that can significantly impact the success of your electronic products. By considering factors such as experience, quality assurance, technological capabilities, and customization options, you can find a reliable partner to meet your needs. Opting for Australian-based printed circuit board assembly services offers additional benefits, including proximity, quality standards, and support for the local economy.

Thoroughly evaluating potential manufacturers through background research, quotes, samples, and site visits will help you make an informed decision. With the right partner, you can ensure high-quality PCB assembly, timely delivery, and overall project success, positioning your products for success in the competitive electronics market.

Do Read Fashion 6 Cell 10.8V 4001Mah-5000Mah Replacement Laptop Battery for Asus