Purpose

Healthcare instruments take various forms, including appliances, in vitro reagents, apparatus, machines, implements, materials, software, or related articles. Skilled individuals use these devices, either individually or in combination, following the manufacturer’s instructions for purposes such as prevention, diagnosis, treatment, monitoring, alleviation of disease, compensation for injury, investigation, replacement, modification, or support of human anatomy.

Methods

Standards are typically utilized voluntarily unless regulatory authorities mandate them. Manufacturers demonstrate that their medical devices comply with the relevant Essential Principles of Safety and Performance, ensuring accessibility to the public.

Results

Numerous national and international standards, industrial standards, manufacturer-developed Standard Operating Procedures (unrelated to international standards), non-recognized standards, and state-of-the-art techniques govern performance, materials, design, methods, processes, or practices in healthcare device production and regulation.

Introduction

Active medical devices rely on an external energy source, distinguishing them from those harnessing human gravity or body-generated energy. These devices transfer substances, power, or components between patients and function as standalone software. Manufacturers ensure both safety and performance by aligning the design of medical devices with their intended purpose and adherence to manufacturer instructions. Regulatory frameworks like the Global Harmonization Task Force (GHTF) help manufacturers understand safety issues and guide medical device regulations.

Objective

This paper establishes harmonized Essential Principles for designing and manufacturing medical devices, ensuring safety and effectiveness. By adopting a standard set of principles across global jurisdictions, regulatory authorities help manufacturers comply with regulations, lower costs, and accelerate patient access to new treatments and technologies.

Emphasis on Essential Principles

This paper focuses on the Essential Principles of Safety and Effectiveness for medical devices and explains the standards’ role in these processes. It underscores the responsibility of manufacturers to identify and mitigate risks associated with their devices, show that benefits outweigh risks, and ensure conformity to essential safety and performance principles. Regulatory authorities assist manufacturers by identifying necessary documents for conformity assessments.

Intended Users

This framework targets regulatory authorities, Conformity Assessment Bodies, industry stakeholders, and others by offering a consistent and efficient approach to medical device control. The framework balances health safeguarding and industry obligations to benefit public health by streamlining processes without imposing unnecessary burdens.

Essential Principles of Safety and Performance

A medical device achieves clinical effectiveness when it produces the intended effect according to the manufacturer’s instructions and aligns with the medical condition it addresses. For instance, a pain relief device must demonstrably relieve pain based on clinical evidence. The Essential Principles of Safety and Performance govern medical device design and manufacturing, encompassing general and design-specific principles. These principles are fundamental in ensuring medical devices’ clinical effectiveness, safety, and performance.

Use of Healthcare Devices Without Compromising Health and Safety

When designing and developing a healthcare apparatus, manufacturers ensure that:

- Any hazards associated with the device align with a high level of health and safety, and they exclude unacceptable hazards after assessing the intended benefit to the patient.

- Under the apparatus’s intended conditions or objectives, clinical conditions, patient safety, and the health and safety of the user or any other individual will not be jeopardized.

A fundamental concept in designing and developing a healthcare device is its safety. Manufacturers conduct a well-reasoned and documented examination of foreseeable risks when using the device and compare these risks with a well-reasoned analysis of the advantages.

Design and Construction of Healthcare Devices to Conform to Safety Principles

Manufacturers must validate the solutions they adopt for safety principles in designing and constructing healthcare devices, considering the generally acknowledged framework. They must recognize issues and associated risks arising from the device’s intended use and predictable misuse. Manufacturers reduce or mitigate these risks by implementing inherently safe design and development policies. When necessary, they ensure appropriate protective measures for risks that cannot be reduced. Finally, they inform users of any remaining risks arising due to limitations in the protective measures implemented.

Healthcare Devices to Be Suitable for the Intended Purpose

Manufacturers design, package, and produce healthcare devices to ensure they are suitable for one or more objectives provided in the definition of a healthcare device in Section 1 of the Medicines and Related Substances Act. Furthermore, manufacturers ensure that the device performs as intended.

Long-Term Safety

Manufacturers design and develop healthcare devices to ensure they are not under stress during everyday use. They also ensure that the device’s characteristics and performance, as described in previous sections, remain unaffected. Manufacturers also consistently maintain and calibrate the device according to the manufacturer’s instructions.

Healthcare Devices are Not Adversely Affected by Transport or Storage

Manufacturers design, develop, and package healthcare devices to ensure that their attributes and performance are not negatively affected during storage and transport, following the instructions and information provided by the manufacturer.

Manufacturers document their review of complaint history and testing evidence to demonstrate that the design, packaging, and production processes ensure the device’s performance and that storage and transport do not negatively influence device attributes.

Benefits of Healthcare Devices to Outweigh Any Undesirable Effects

Manufacturers ensure that the benefits of using a healthcare device for its intended performance outweigh any undesirable effects. To comply with this essential principle, they identify and document any unwanted effects and the advantages they anticipate from using the device. Manufacturers must offer evidence regarding the risk analysis results based on a documented review of their experience with the device.

Chemical, Physical, and Biological Properties

Manufacturers focus on the chemical and physical properties of the materials used in the device to ensure they meet the general principles for healthcare devices. Manufacturers ensure compatibility between biological tissues and materials, body fluids, specimens, and cells, depending on the device’s targeted objective. They design, produce, and package healthcare devices to ensure that any risks related to residues and contaminants do not affect individuals engaged in storing, transporting, or using the device. Additionally, they provide the device to be used safely with any substance, gas, or material that may come into contact with it during everyday use. If healthcare devices include or are designed to include a substance considered a medicine, manufacturers verify the substance’s quality and safety according to the medicines’ instructions.

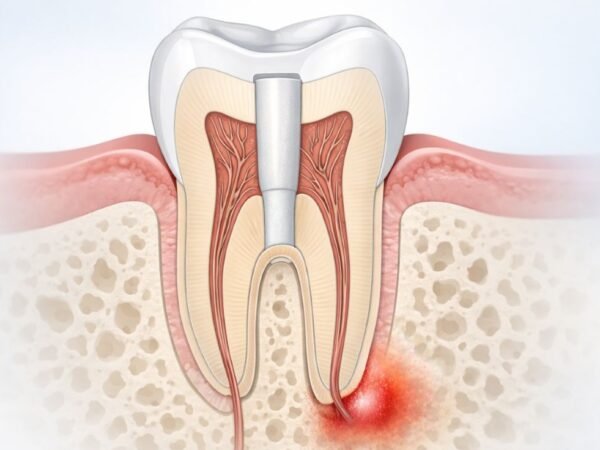

Infection and Microbial Contamination

Manufacturers design healthcare devices to reduce the risk of contamination between the device, specimen, patient, or another person. Manufacturers follow adequate veterinary controls and supervision if the device includes tissues, cells, or substances originating from animals. The production process integrates validated methods for removing or inactivating viruses and other transmissible agents. Manufacturers supply healthcare devices in a sterile state for storage and transport. They meet adequate standards for air quality in manufacturing areas where the device is produced. Manufacturers design packaging to withstand the sterilization process, allowing the sterilizing agent to permeate while maintaining sterility for a specified period after the process.

Constructive and Environmental Properties

Manufacturers conduct a documented and well-reasoned risk analysis for all other devices intended to be used for the targeted objective. They provide all the necessary information for using the device alongside another healthcare device. Manufacturers document evidence of adequate testing processes to confirm that healthcare devices operate safely, regardless of any impairment to the intended performance. The analysis lists all potential causes and explains the probability and severity of their presence for each risk.

Healthcare Devices with a Measuring Function

Manufacturers design and produce healthcare devices with a measuring function to ensure accuracy, precision, and stability within the prescribed limits based on the device’s targeted objective. They follow product standards, applicable guidance documents, and pharmacopeia monographs to ensure the device is designed and produced acceptably.

Protection Against Radiation

Manufacturers design and produce healthcare devices to minimize the patient’s and user’s exposure to radiation, limiting it to the levels needed for the device’s diagnostic and therapeutic functions. Manufacturers reduce hazardous levels of visible or invisible radiation to medically essential levels. Devices must guarantee the reproducibility and tolerance of relevant variable parameters.

ISO 14971: Healthcare Device Risk Management

ISO 14971 is the standard that defines the requirements for manufacturers to manage the risks associated with healthcare devices throughout their product life cycle. It was developed by a group of technical experts from the ISO Technical Committee (TC) 210 and IEC TC 62.

Classification of Healthcare Devices

Manufacturers classify healthcare devices based on their risks to patients, users, and other individuals involved. The following list outlines the criteria for categorizing healthcare devices:

Sources

- National Center for Biotechnology Information (NCBI). NCBI Website.

- IMDRF Good Regulatory Review Practices Group. Essential principles of safety and performance of medical devices and IVD medical devices. 2018. Available from the IMDRF Official Website. Accessed: January 31, 2020.

- World Health Organization. Medical Device Regulations: Global Overview and Guiding Principles. World Health Organization; 2003. Available from the World Health Organization Website. Accessed: January 31, 2020.

- Force GH. Summary technical documentation for demonstrating conformity to the essential principles of safety and performance of medical devices (STED). SG1/N011R17. 2007.

- Force GH. Essential principles of safety and performance of medical devices. Available from the IMDRF Official Website. Accessed: January 31, 2020.

- The Regulation of Medical Devices in Australia. Therapeutic Goods Administration, Department of Health, Australia; 2002. Available on Google Scholar.

- The Essential Principles for Medical Devices. Australian Medical Devices Guidance Document, 22. 2003. Available from the Omnex Website. Accessed: January 31, 2020.

- Dr.Sono. A constant friend for selling your most needed, latest medical devices.

Do Read: The Importance of Proper PPE Waste Disposal: What You Need to Know